Considerations when using steam

How to maximize the thermal energy transfer when heating bulk materials with an MBHE

Author: Caio Raineri, Global Services and Support Manager, Solex Thermal Science

One of the many benefits to heating free-flowing bulk materials with plate-based moving bed heat exchangers (MBHEs) is the ability to use steam as a heat source, providing the opportunity to reduce the size of the equipment.

There are two key considerations when doing so to maximize the thermal energy transfer efficiency:

- The steam must be saturated.

- The condensate formed in the plates must be efficiently removed. This is the only way to ensure the highest heat transfer coefficient.

(To learn more on steam theory, TLV Group offers a more detailed description on steam traps, condensate recovery and steam theory).

Ensuring saturated steam

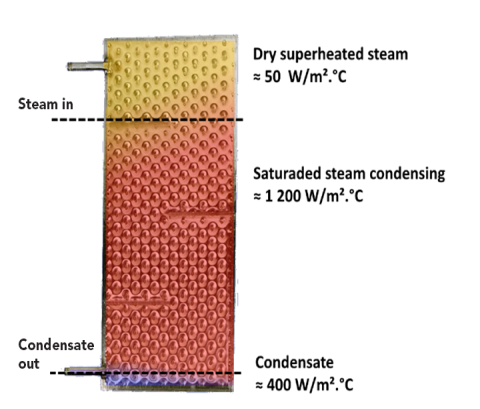

To start, a common misconception is that, because superheated steam has a higher temperature than saturated steam at the same pressure, it should increase the performance of the heat exchangers. In fact, superheated steam decreases the heat transfer by more than 95%, and thereby decreases the performance of the energy that is being exchanged, as shown on the illustration below.

Note: Heat transfer coefficient shown is for illustrative purposes only. Actual values differ based on various factors.

A sound understanding of steam properties and behaviour is required to ensure saturated steam is delivered to the plates. For example, if your MBHE is designed for 134°C saturated steam (e.g., 2 barg) and you have saturated 10 bar steam (≈184°C) available in your plant, simply installing a pressure reducing valve to drop the steam pressure to 2 barg would generate superheated steam somewhere around 159°C (instead of 134°C).

Therefore, when the steam comes from a higher-pressure line, you need to install a desuperheater. This is typically a water spray nozzle that cools down the steam after the pressure reduction valve to ensure that the steam temperature arriving at the manifold to the MBHE will be at the required saturation pressure and temperature.

Efficiently removing condensate

Next, each bank within a vertical plate MBHE typically consists of dozens of individual plates that are connected in parallel through the upper and lower manifolds. Each bank of the unit is considered a different exchanger, each with different heat loads for several reasons.

This specific configuration requires a dedicated steam trap on each bank to avoid what is referred to as the group trapping phenomenon.

Source: https://www.spiraxsarco.com/learn-about-steam/condensate-recovery/layout-of-condensate-return-lines

It is important to make sure the mechanical design of condensate piping, the steam trap locations and condensate collector design allow for continuous extraction of the liquid without the risk of flooding the plates. Condensate buildup or back pressure in condensate lines can lead to undesirable flooding of the plates and negatively impact heat transfer performance.

If the condensate after the steam traps is not free flowing downward to a condensate reservoir operated at atmospheric pressure, you will need to install a condensate pump to avoid the flooding of the plates.

Removal of non-condensable gases

Lastly, to maintain the performance of the MBHE and avoid decreasing the heat transfer coefficient, it’s also important to account for the removal of air and non-condensable gases from the steam system.

Automatic air vents, also known as deaerators or air bleeding valves, need to be installed upstream or downstream of the plate bank inlets – typically on the common manifold of each of the banks.

Checklist

Ensuring saturated steam:

- Is the steam used to feed the MBHE coming from a reduction valve? If yes, at what pressure?

- Is there a de-superheater installed on the line?

- Is saturated steam only supplied to the MBHE?

Efficient condensate removal:

- Have you considered individual steam traps on each bank?

- Is the condensate piping free flowing downwards?

- Is there a condensate pump to avoid back-pressure?

Removal of non-condensables:

- Are there automatic deaerators in the steam lines?

Learn more

Solex’s team of skilled engineers are available to help provide recommendations and assistance in using steam with a moving bed heat exchanger. We additionally recommend reviewing your steam and condensate system set-up with an independent steam professional to avoid interferences between your plant’s steam-consuming equipment, ensure best practices for installation and benefit from optimal performance.

Want to discuss further? Contact a Solex team member today.

Also from the blog

How to know it’s time to tune-up your heat exchange technology

Putting industrial waste heat to work

Solex featured in new book on ammonium nitrate, fertilizer safety

This entry was tagged Heating, and last updated on 2023-5-10