Cement production and cooling

What is cement?

Cement is the combination of calcium carbonate, silica, alumina and ferrous oxide, which are naturally found in limestone rock, chalk, shale and/or clay.

During the cement production process, these minerals are fused together by heating them to just under their melting point, forming a cement clinker between 3 to 20 mm in diameter. Pure cement is formed when the cement clinker is ground into a fine powder.

To regulate how cement mortar or concrete will set, gypsum is added to this powder. Gypsum is a mineral consisting of hydrated calcium sulfate that influences cement’s reactivity with water. Cement, when combine with water, aggregate and sand forms concrete or with sand alone forms mortar. Once hardened, these are the solid, strong construction materials that we are more familiar with.

How is cement produced?

The cement production process begins with the aforementioned raw materials being crushed and homogenized into a powder, using specific ratios of each material. The fine powder is pre-heated and calcined, then moved into a large, rotating drum known as a kiln. The kiln is slightly inclined to allow the product to move downwards towards the discharge end.

The powder entering the kiln is heated to approximately 1,450ºC. At these high temperatures, chemical reactions occur that form the cement clinker. Upon exiting the kiln, the cement clinker is cooled to approximately 80ºC. Gypsum is then added to the composition and the cement clinker is ground down into cement powder, ready for storage, packaging and transport.

How is cement cooled?

Cement cooling is an important step in the cement production process, as it reduces the chance of gypsum dehydration and the formation of lumps, reducing the overall quality of the final cement.

The end users of cement are also demanding lower cement temperatures in order to minimize the evaporation effect on the final concrete mix, enabling them to improve quality control and achieve more consistent concrete strengths.

The end users of cement are also demanding lower cement temperatures in order to minimize the evaporation effect on the final concrete mix, enabling them to improve quality control and achieve more consistent concrete strengths.

Conventional cement cooling technology has had few advances in the last several decades and are burdened with efficiency and maintenance issues. The conventional design is a cylindrical tube, with an internal ribbon-screw, which elevates the cement and keeps it in contact with the interior surface of the tube. Water is then poured over the exterior tube, cascading down the outside wall, achieving indirect heat transfer, cooling the cement.

This conventional cement cooling technology typically results in dust build up along the outside of the cylindrical tube, which acts as an insulator preventing efficient and effective heat transfer. Water flowing over the tower is also difficult to control, resulting in the over-usage of water and increased facility costs.

High maintenance costs are also associated with conventional cement cooling technologies, as regular maintenance is required to prevent caked and solidified material build up inside and outside the tower.

Lastly, there is a negative environmental impact on air emissions from the dusty mill house and contaminated water from the cooling process.

Lastly, there is a negative environmental impact on air emissions from the dusty mill house and contaminated water from the cooling process.

More effective cement cooling technology

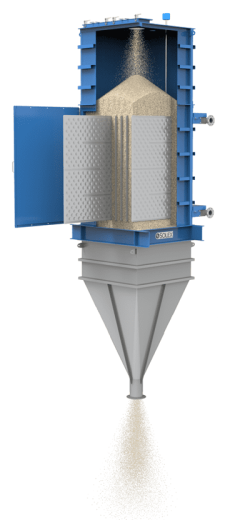

Plate-based moving bed heat exchangers (MBHEs) offer a more efficient solution for the cement cooling process.

They are comprised of a series of vertical, hollow, steel plates within an enclosed casing. Cement enters the unit, flowing downward at a uniform velocity between the plates. Cooling water flows countercurrent within the plates, cooling the cement indirectly (e.g., by conduction) to its final stable temperature.

Plate-based MBHEs can consume up to 90% less energy than conventional technologies. In some cases, they allow for energy recovery loops — thereby increasing overall efficiencies.

Since the unit is fully enclosed, there are also no dust emissions. The modular design and small footprint allow for facility retrofits and simple capacity increases.

With no moving parts and easy access to individual plates, maintenance costs are lowered, ensuring long-term reliable operation.

Learn more about by visiting http://solexthermal.com/heat-exchanger-applications-and-industries/cement/

This entry was last updated on 2023-3-22

Return to Articles