The rise of compact design

How MBHEs free up floor space without sacrificing performance

Author: Jamie Zachary

How to increase production capacity without expanding the facility’s footprint? It’s a question most industrial processors have faced at one point or another.

Real estate within plants is often limited. Building expansions or greenfield projects come with significant costs, permitting hurdles and long timelines. This means operators are under pressure to find smarter, space-efficient solutions that maximize throughput within existing footprints.

According to several industry analyses, space constraints rank among the top obstacles when upgrading or modernizing manufacturing operations. For example, a recent North American oilseed processing report cites that many processors want to modernize aging equipment, increase efficiency and adopt newer technologies, but are hampered by existing infrastructure capital, and operational constraints.

Meanwhile, a global foundry equipment market report forecasted that foundry and casting manufacturers will be spending billions of dollars globally between now and 2030 modernizing their existing foundry floors to meet tighter specs and labour constraints.

Some operators are finding ways to push through these barriers. Richardson International just recently doubled canola crush capacity at its plant in Yorkton, Sask. The modernization, which was completed this past summer, included optimizing existing infrastructure and upgrading facilities.

Cargill is only a few years from having completed a massive modernization of its soy crushing and refined oils facility in Sidney, Ohio, that nearly doubled crush capacity in its existing footprint. Many additional expanded soybean processing facilities are scheduled to come online in the U.S. over the next few years.

In the metalcasting industry, meanwhile, Waupaca Foundry recently expanded production capabilities at its flagship Plant 1 in Wisconsin – not through a greenfield build, but by adding horizontal molding to existing vertical molding capabilities.

“Space is a premium in many plants,” says Jill Caskey, Global Sales Director at Solex Thermal Science. “In many cases, the ability to fit new equipment within the same square footage can have a significant impact on the decision for a project to move forward.

“This reality is pushing plant operators and engineers to rethink process equipment design — seeking solutions that balance compact layouts with high-throughput performance.

Space-saving process equipment

Widely relied upon in many different industry processes, plate-based moving bed heat exchangers (MBHEs) provide an effective, efficient and compact solution for operators who are rethinking their thermal treatment processes.

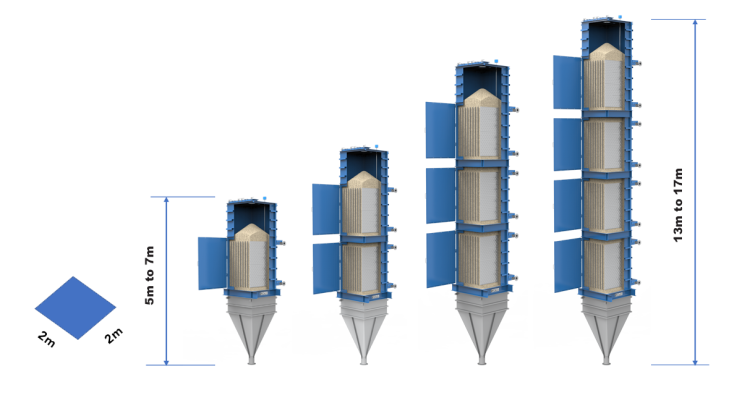

Conventional rotary drums or fluidized beds require large horizontal footprints that typically measure up to several metres in diameter and 10s of metres in length. In comparison, plate-based MBHEs are built with a vertical orientation, typically with a plan area of two metres by two metres.

While plate-based heat exchangers for bulk solids may be taller than rotary drums, for example, they are still often smaller overall. This is due to the difference in how the heat transfer takes place. Plate-based MBHEs use flat heat exchange plates, compared with tubular heating elements required in most other indirect heat exchangers. For a given volume, plate-type heat exchangers contain more than double the heat exchange surface area of a tube-type heat exchanger.

This compact design allows these types of MBHEs to be installed in tight spaces, integrated into existing buildings or stacked as part of a modular heat exchanger design.

“With plate-based MBHE technology, you can achieve the same or better performance as larger systems, but within a much smaller footprint,” says Caskey. “That’s a game-changer for operators who are landlocked or looking to retrofit without major construction and downtime.”

Enabling retrofits and brownfield expansions

Because plate-based MBHEs occupy less space, they can easily integrate within brownfield sites without extensive structural changes. Solex Chief Sales Officer Igor Makarenko notes this is particularly valuable in industries such as fertilizers, chemicals, polymers and minerals, where existing facilities are built and expected to operate for decades but must evolve to keep pace with production demands.

“We are seeing growing interest from operators who want to expand throughput but can’t justify a new building or major expansion,” he says.

“Plate-based MBHEs give them that flexibility. They can add capacity within the walls they already have, saving both time and capital.”

In addition to direct space savings, the design of plate-based heat exchangers also provides the bonus of modular configurations. Heat exchanger banks can be added to reflect changes in production needs. Plants can subsequently grow stepwise without needing to tie themselves to large, one-off infrastructure projects.

Performance without compromise

One of the biggest questions of space-saving solutions is whether performance or product quality will be negatively impacted. Plate-based heat exchangers address this concern by delivering high throughput with gentle handling and precise temperature control. Because the heat transfer process is indirect, these MBHEs also eliminate issues such as material contamination or uneven heating/cooling, which are sometimes associated with direct-contact systems.

Operators also benefit from lower maintenance requirements, as plate-based MBHEs have fewer moving parts than rotary drums or fluidized beds. This provides greater uptime and more stable operations — key factors for industries where even minimal delays can translate into hefty costs or missed production targets.

“MBHEs are the best of both worlds,” says Makarenko. “They combine compact design with precise temperature control and high throughput, so operators don’t have to choose between saving space and maintaining performance.”

Key takeaways

- Compact design without compromise: Plate-based heat exchangers enable high-throughput bulk solids cooling and heating in a compact footprint.

- Brownfield or retrofit flexibility: These vertically oriented MBHEs fit within existing plants, supporting expansions without costly building additions.

- Proven, trusted technology: Plate-based systems have a long track record in many industries.

- Optimized production: Operators can realize greater capacity and throughput without sacrificing performance.

Discover how our heat exchangers can simplify your plant design. Contact our team to explore design options for your plant.

This entry was tagged Heating, Cooling, and last updated on 2025-9-15