Maximizing plant uptime

Heat exchange reliability in harsh industrial environments

When equipment fails, the costs extend far beyond repairs. In sectors such as potash and chemicals, an unexpected shutdown can halt production for days — or even weeks — while maintenance teams diagnose the problem.

For many operations, that downtime often comes back to one culprit: corrosion.

A loss-prevention bulletin from Institution of Chemical Engineers (IChemE) states that about 70% of losses occurring in industry can be traced back to corrosion. Beyond repair costs, these interruptions often disrupt downstream systems, compromise product quality and stretch already-tight maintenance schedules.

“Every percentage point of uptime matters,” says Jean-Marc Reichling, Global Sales Director at Solex Thermal Science. “When a plant operates in a corrosive or high-temperature environment, even minor material degradation can have major operational consequences. That’s why reliability starts with design and with choosing the right materials from the outset.”

Why corrosion control is central to uptime

In processes involving chlorides, acids or abrasive solids, traditional shell-and-tube or fluidized bed heat exchangers can suffer from erosion and pitting over time. These corrosive agents attack metal surfaces, gradually thinning tube walls and weakening welds — especially in areas involving turbulent flow or stagnant zones. Over time, this localized degradation can lead to leaks, reduced heat transfer efficiency and even catastrophic equipment failure if left unchecked.

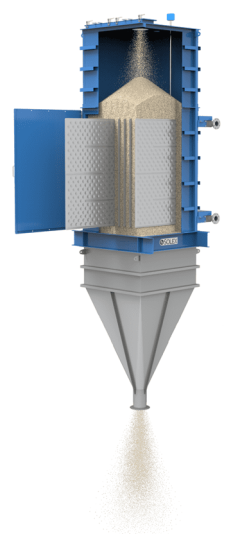

Unlike rotating drums or fluidized beds that rely on moving parts, plate-based moving bed heat exchangers (MBHEs) use gravity to transfer material across vertically stacked plates — eliminating mechanical wear points and minimizing maintenance needs.

“Fewer moving parts means fewer failures. Operators in potash or chemical environments are looking for equipment they can trust to perform consistently between maintenance cycles," says Igor Makarenko, Chief Sales Officer at Solex, adding the right material selection — whether that’s a high-nickel alloy, duplex stainless steel or specialized coatings — is also key to that reliability.

“Fewer moving parts means fewer failures. Operators in potash or chemical environments are looking for equipment they can trust to perform consistently between maintenance cycles," says Igor Makarenko, Chief Sales Officer at Solex, adding the right material selection — whether that’s a high-nickel alloy, duplex stainless steel or specialized coatings — is also key to that reliability.

How plate-based heat exchangers handle corrosive environments

Plate-based moving bed heat exchangers operate through indirect heat transfer. Solids such as potash or polymer pellets move slowly by gravity between a series of vertical plates, while a cooling or heating medium — typically water, glycol or thermal oil — flows through the enclosed plates on the opposite side.

Because there’s no direct contact between the product and the heat transfer fluid, MBHEs protect against cross-contamination and corrosion from aggressive process streams. The enclosed design also shields internal surfaces from airborne dust and chemical vapors that often accelerate wear in open systems.

For example, in potash operations, airborne chlorides are a well-known source of equipment corrosion. Solex’s proven potash cooling solutions use corrosion-resistant alloys and precise temperature control to ensure consistent cooling performance over years of operation, even in high-humidity and high-chloride environments.

Material selection is another critical factor. While standard MBHE construction often begins with 316-grade stainless steel, Solex also engineers units from duplex stainless steels, titanium or high-nickel superalloys such as Inconel 617 or 625 for severe-duty applications. These materials offer excellent resistance to chloride-induced pitting, acid corrosion and high-temperature oxidation — all common challenges in chemical, fertilizer and mineral processing plants.

Reliability in corrosive service environments depends not only on material choice, but also on thermal and mechanical predictability. Plate-based MBHEs distribute material evenly across each plate, reducing hot spots and stress points that can lead to localized corrosion or scaling.

Key uptime-enhancing advantages include:

- Reduced maintenance frequency: No rotating parts or high-velocity gas streams means less wear and fewer shutdowns for repairs.

- Longer equipment life: Corrosion-resistant materials such as duplex stainless steel, titanium or high-nickel alloys extend operating lifespans.

- Improved process consistency: Uniform temperature control prevents build-up, fouling, or material degradation that can trigger unplanned maintenance.

- Simplified inspections: Easy access to plate bundles allows for quick cleaning and condition checks during scheduled outages.

“Our clients often tell us that reliability isn’t just about reducing downtime — it’s about building confidence that their process will run as planned, day in and day out,” says Makarenko. “That’s what a corrosion-resistant heat exchanger should deliver.”

Beyond potash: A lesson for all corrosive environments

While potash is among the most aggressive industries in terms of corrosion exposure, the same design principles apply across many chemical operations. A joint report by the Association for Materials Protection and Performance (AMPP), World Corrosion Organization (WCO) and the European Federation of Corrosion (EFC) estimates corrosion costs the global economy more than $2.5 trillion annually.

“Reliability is the product of smart engineering and experience,” says Reichling. “Our systems are built to perform in the toughest environments because we’ve designed them with decades of data from real-world conditions.”

Learn more

Curious how Solex tackles corrosive cooling demands? Explore our insights into corrosion-resistant systems, and reach out to discuss how similar solutions could enhance your plant process.

This entry was last updated on 2025-10-21